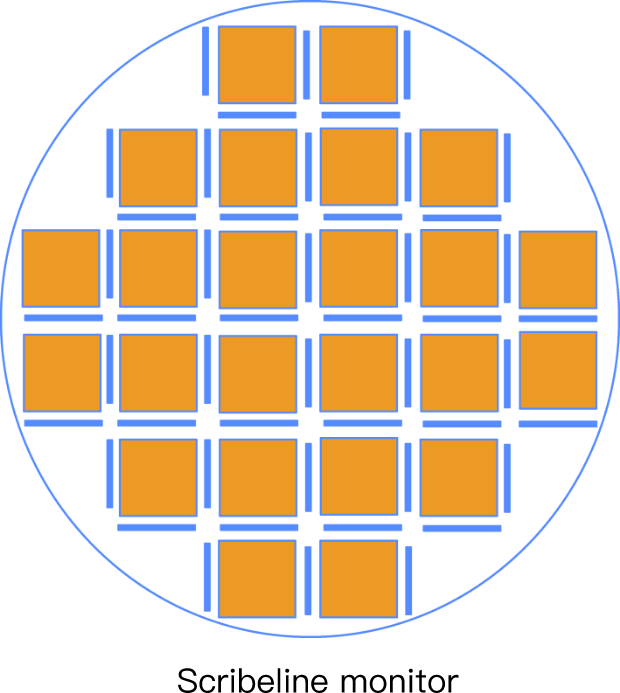

Key Components

Significant advantages of Semitronix solution

- Compared to traditional PCM, Semitronix solution offers stronger process monitors to achieve more robust production yield, stability and predictability

- Maintain production quality with reduced cost

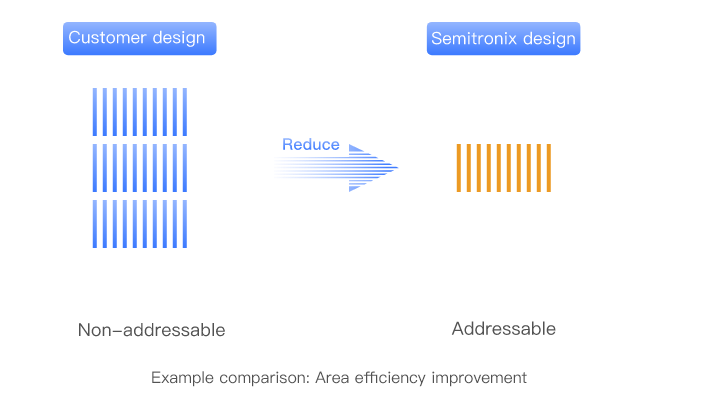

Design

- Addressable solution significantly improves design efficiency

Related Products: ATCompiler / Dense Array

Example comparison: Area efficiency improvement

- Reducing the customer's original full PCM area by 60% to improve DUT coverage in a smaller area

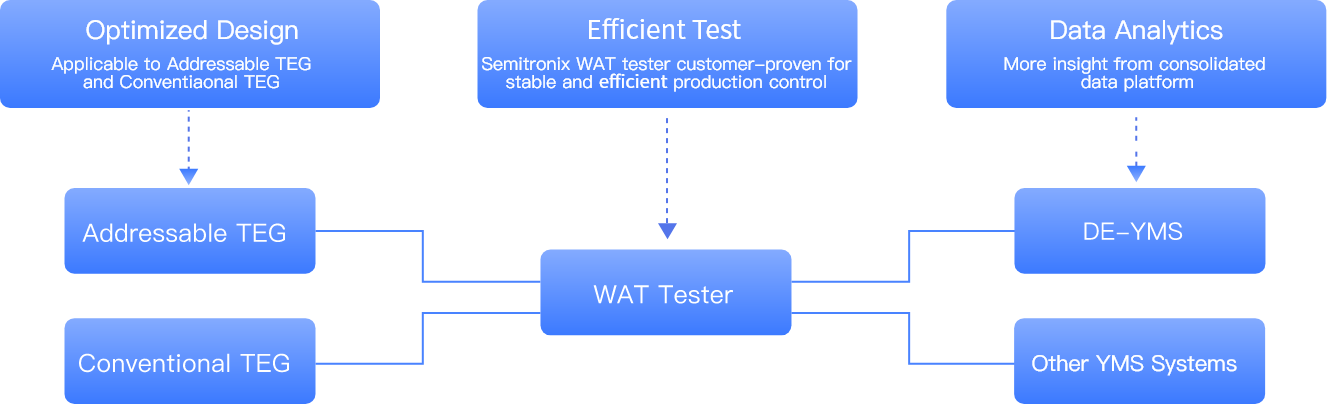

Testing

- Test acceleration: 1.4X to 5X WPH

- Production EAP system integration

- Data matched to foundry requirements

- Field proven for production application at leading foundries

Related products: WAT Tester

Data Analysis

- DataExp analytics platform facilitates analytics flow automation, standardized with integrated back-end production databases.

- In-depth analysis from traditional individual parameter control to exploring insights and actionable feedback from multi-dimensional data sources.

Related products: DataExp-General / DataExp-YMS / DataExp-TMA

Enhanced process control

Enhanced process control High quality feedback

High quality feedback Cost reduction

Cost reduction